Complete Digital Engineering Services

Creation of 3D models, 3D scanning, photogrammetry, and production drawings.

How It Works:

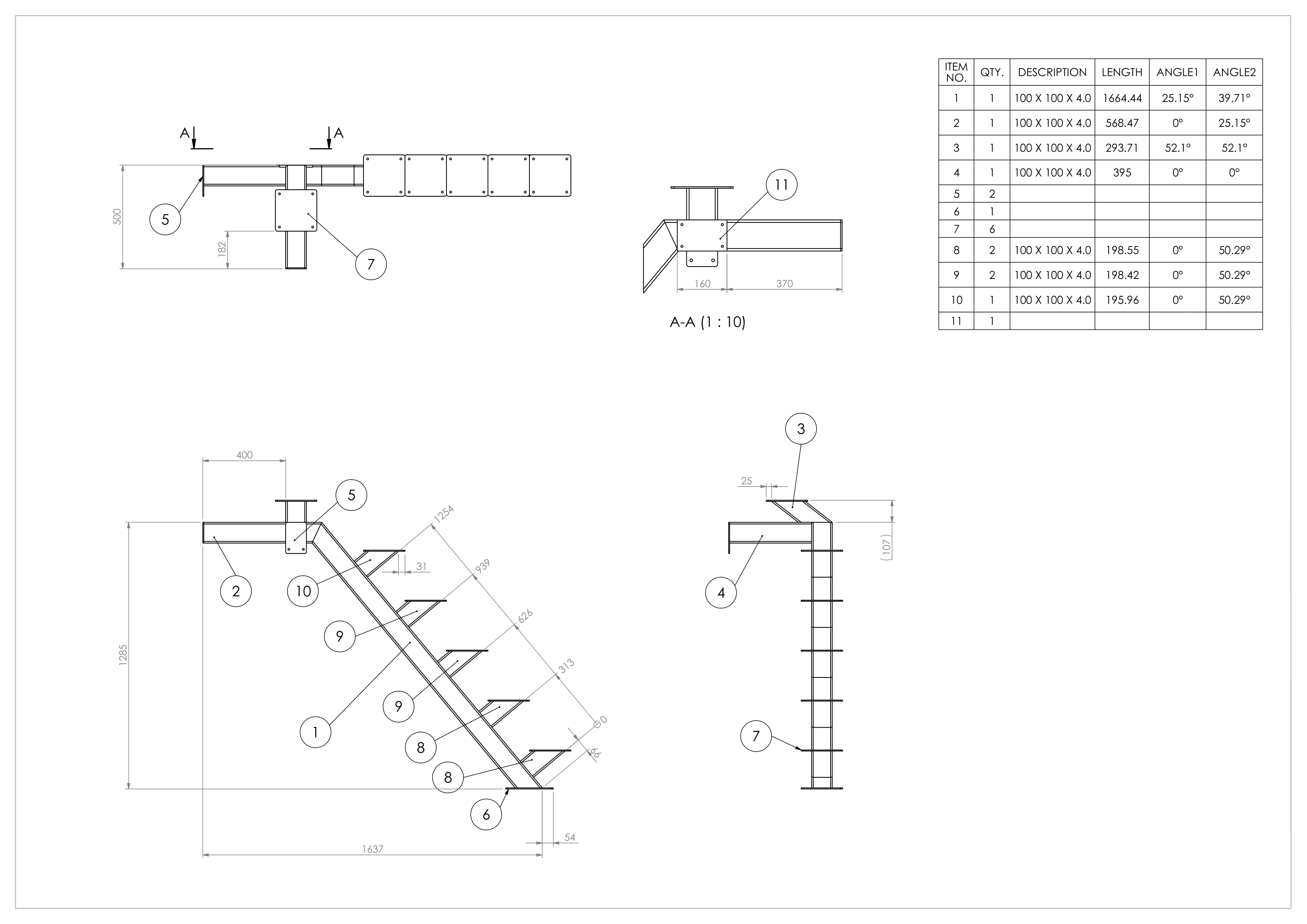

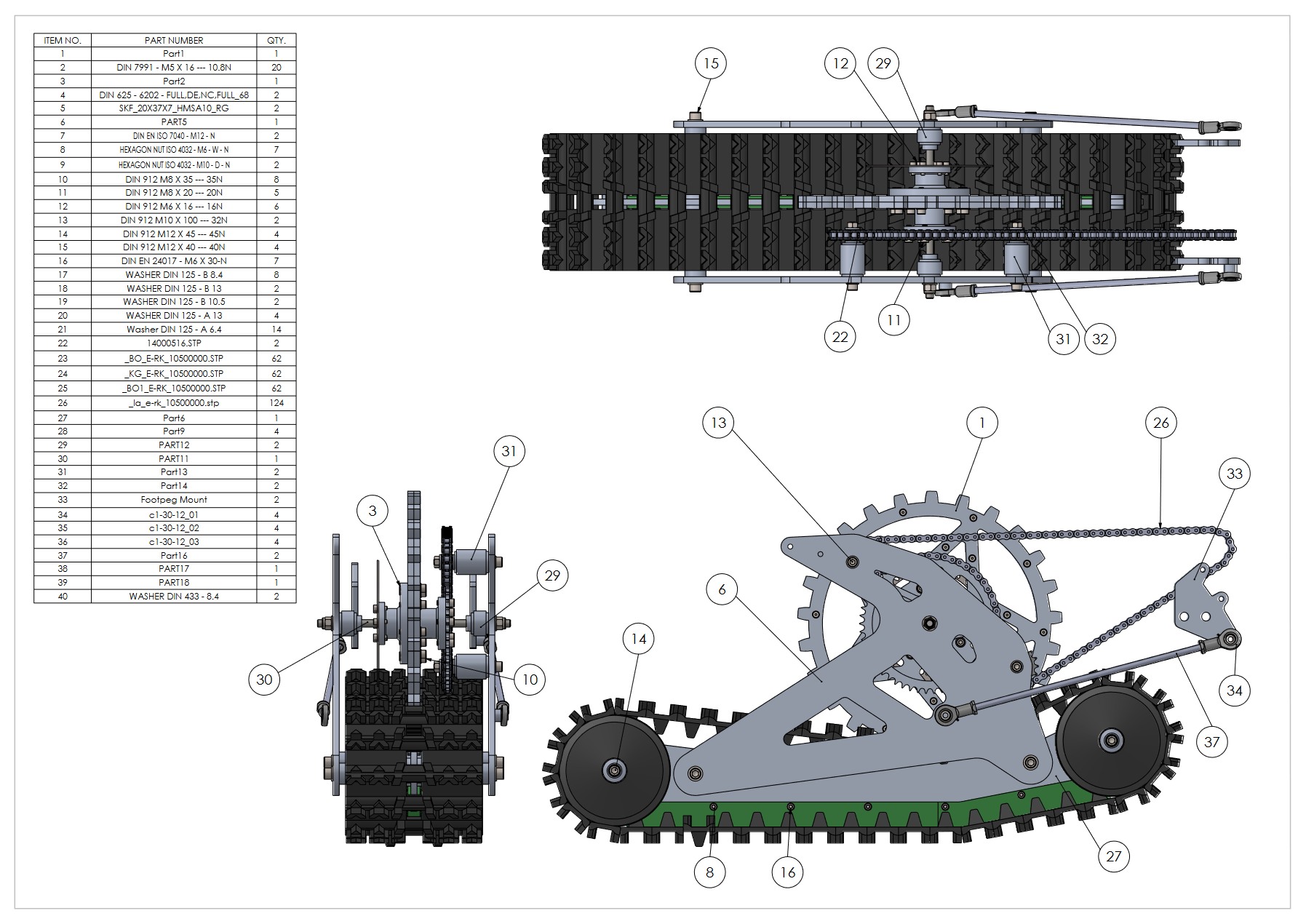

Design and manufacturing of a modified conveyor.

The task was to develop a new conveyor based on the existing one and install at another branch with certain changes and additions taken into account.

1. Scanning:

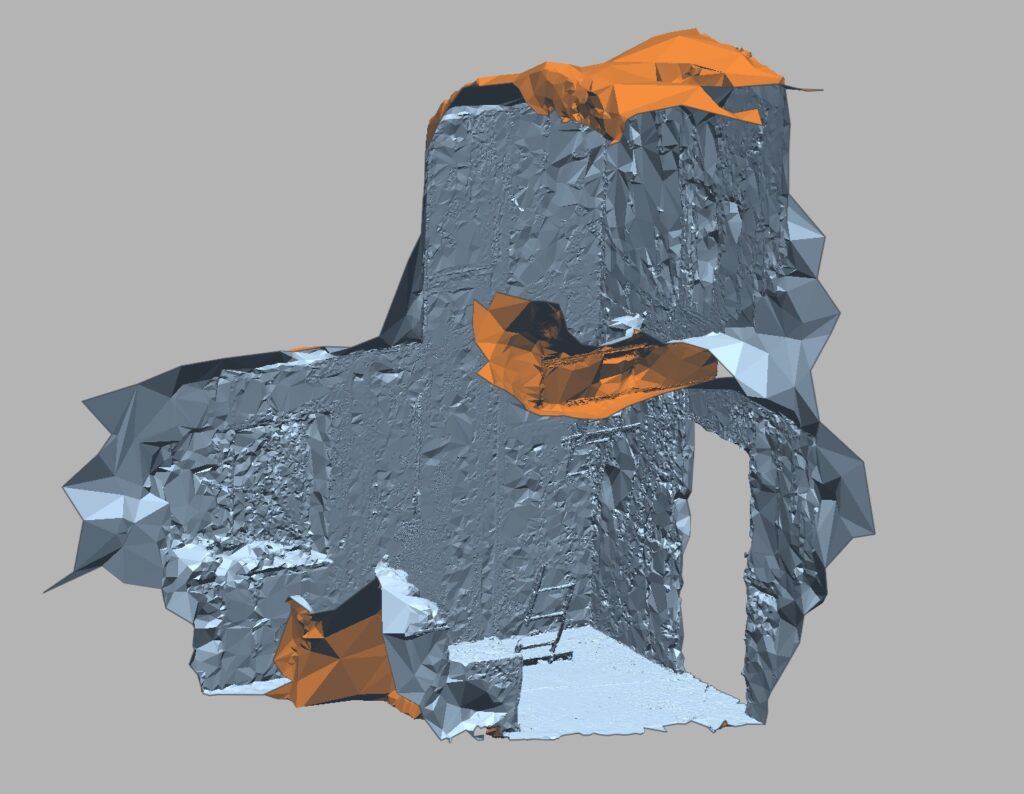

First, we made full scanning of both the conveyor itself and the space of the new branch where it is to be installed. The photogrammetry method enabled us to obtain digital models of both objects, which is key to successful design.

2. Processing and Alignment of Scans:

Then we processed the obtained scans, removing all unnecessary elements and refining the models to match real objects. This ensured that our design work would be as accurate and efficient as possible.

3. Development of an individual project:

Based on the scanning data, the conveyor model was adapted to fit seamlessly into the new conditions, taking into account all the requirements and preferences of the customer. Structural changes were made and new elements were added to enhance the functionality and efficiency of the conveyor.

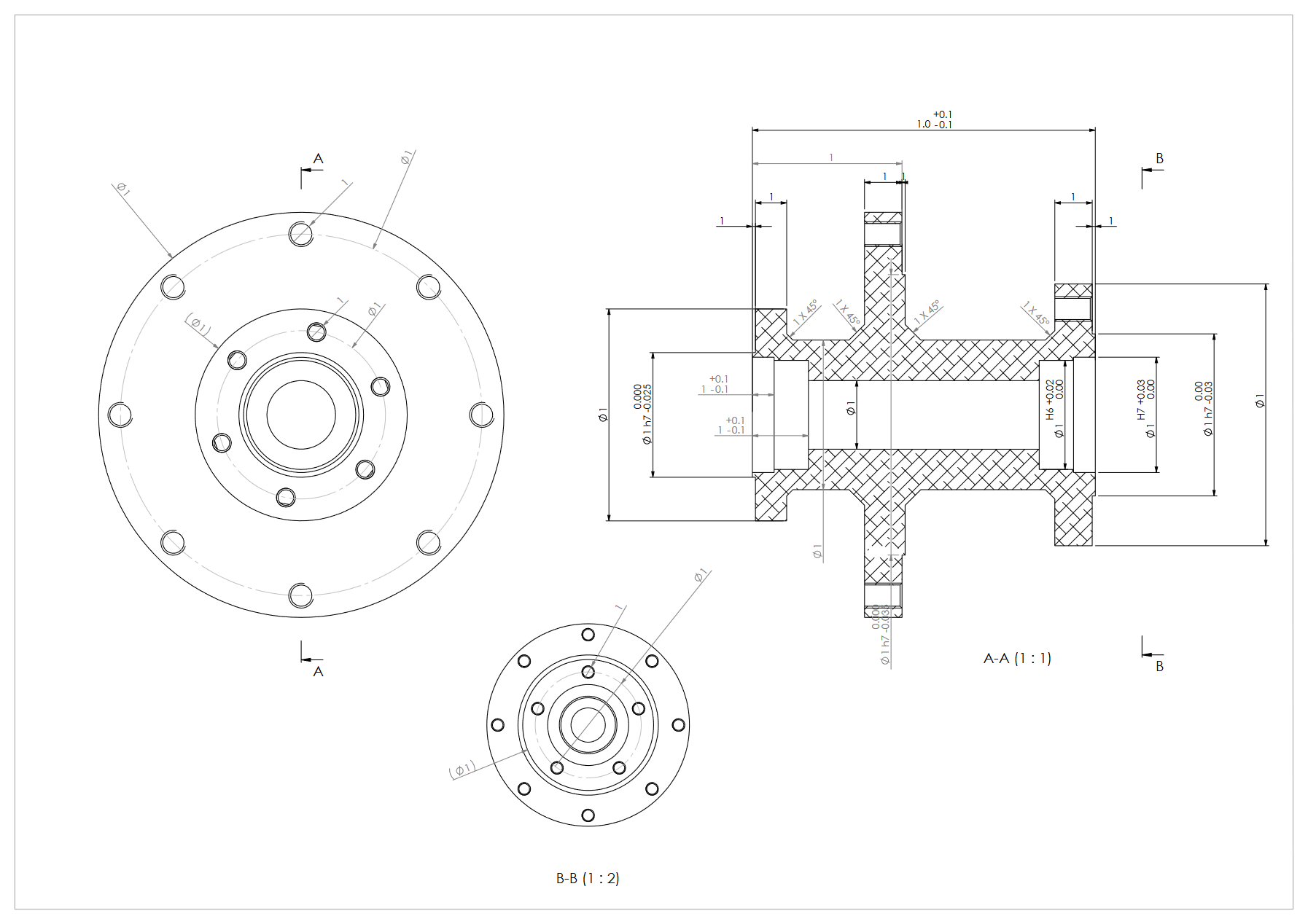

4. Creating drawings for production:

Based on the modified model, a complete set of technical drawings and documentation required for the manufacture of a new conveyor was prepared. These documents contained all the details and specifications.

5. Manufacturing and installation:

After the completion of the manufacturing process, the new conveyor was delivered and installed. Thanks to meticulous planning and precision at all stages of the work, the conveyor not only fit perfectly into the allocated space but was also improved according to the customer’s wishes.

The process of creating a custom staircase using 3D scanning.

A client approached us with the desire to install a perfectly fitting staircase for a specific opening in their home, and we used modern technologies to turn their dream into reality.

1. Scanning the aperture:

First, we conducted a detailed scanning of the opening using a method called photogrammetry. This means that we took a series of photographs of the opening from different angles in order to create an accurate digital copy (scan) of this space.

2. Scan Processing:

The obtained digital image of the opening was then meticulously processed. We removed any distortions and extraneous details to achieve a clean and accurate 3D image. Then, we aligned the model so that all its elements were perfectly positioned relative to each other, just as in reality.

3. Creating a Staircase Model:

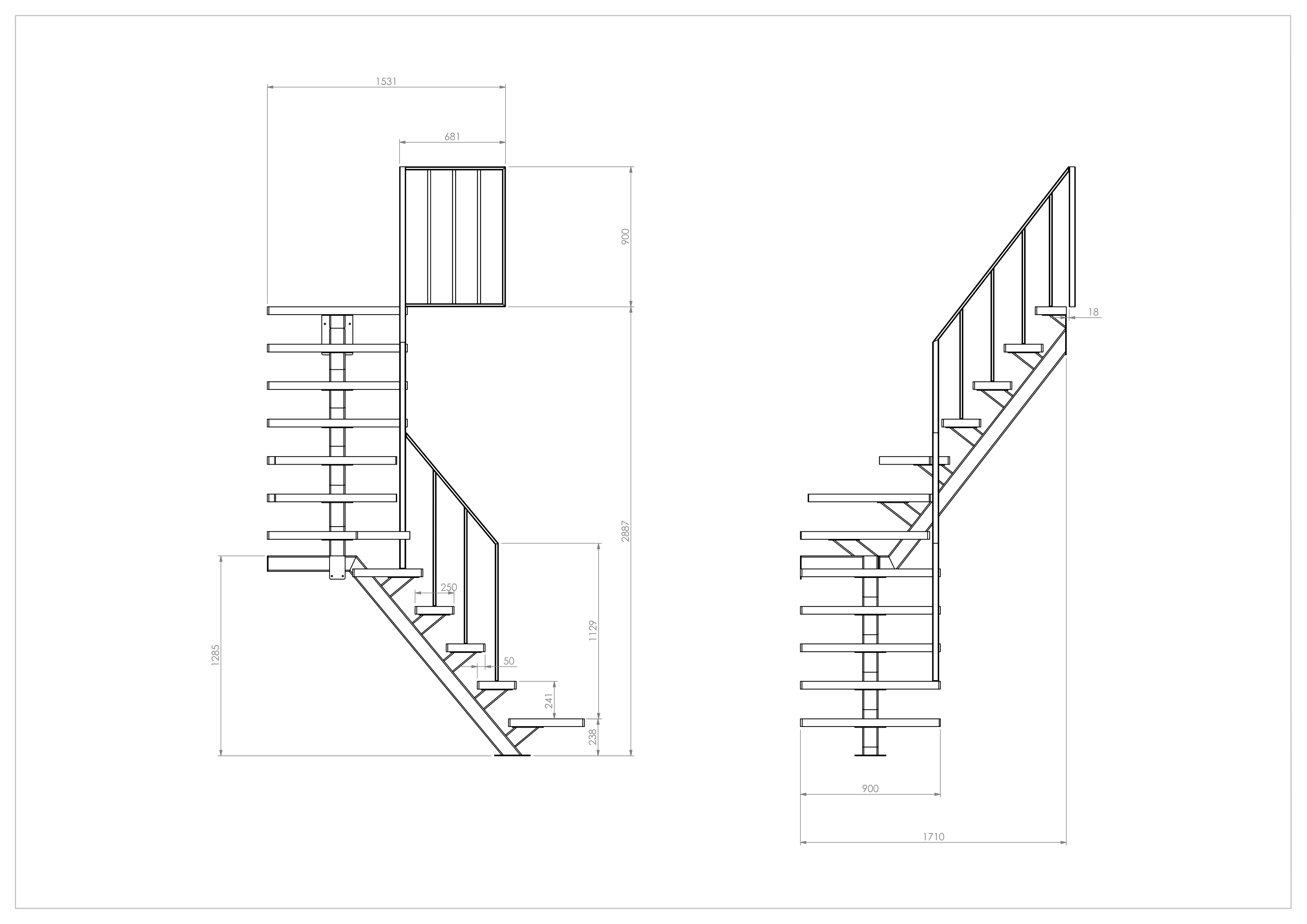

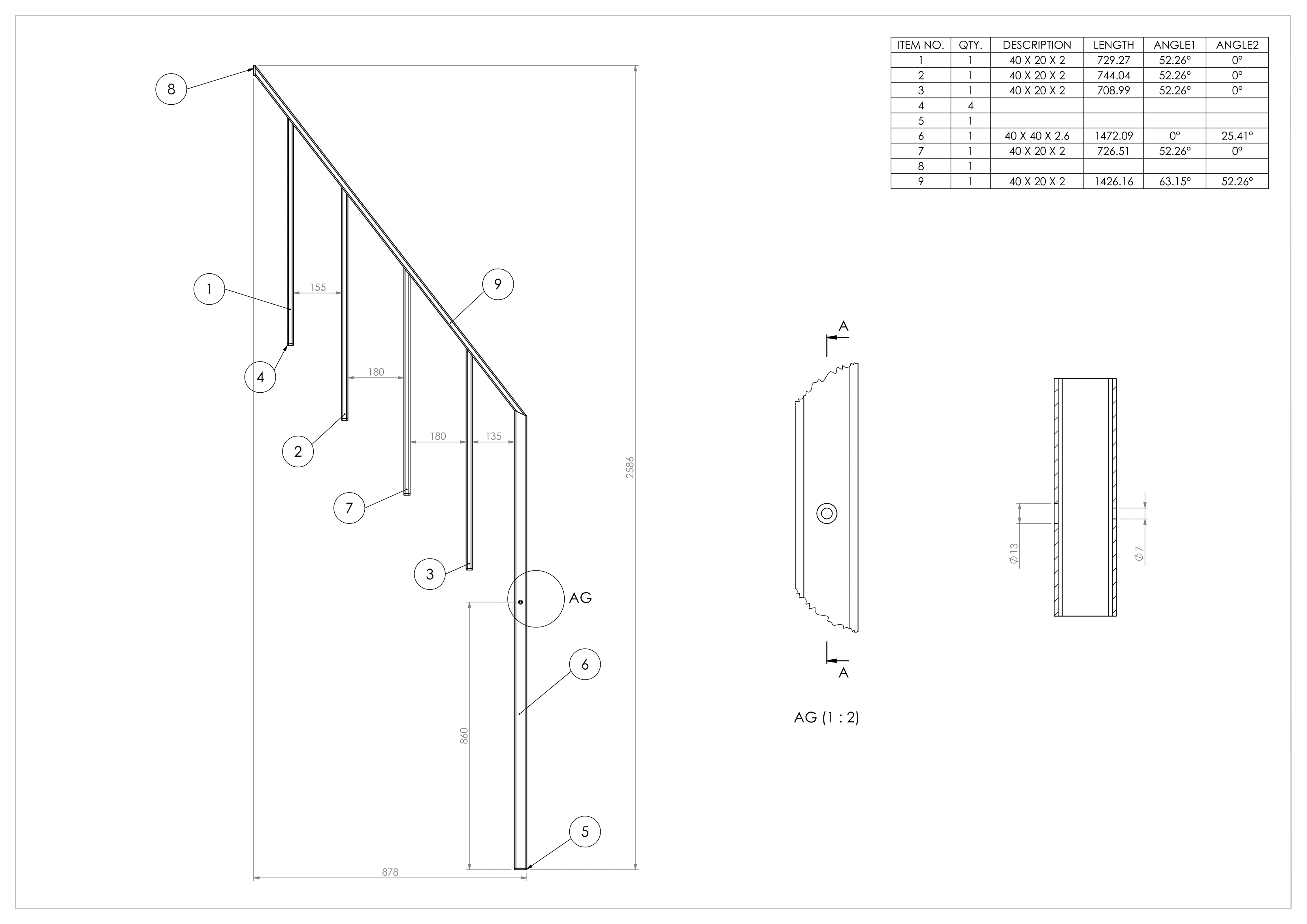

Using this precise digital image of the opening as a foundation, we developed a unique 3D model of the staircase. We took into account all the client’s wishes regarding the appearance and functionality of the staircase, ensuring it harmoniously fits into the space.

4. Drawings prepartion:

Based on this model, we created detailed drawings and plans necessary for the construction of the staircase.

5. Manufacturing and Installation:

Following these drawings, the staircase was manufactured with high precision. Upon completion of the production process, it was delivered to the site and successfully installed. As a result, the client received a perfectly fitting staircase that matches the interior and meets all of their requirements.

Converting an electric bike into a winter version using 3D scanning.

With a passion for technical experiments and a love for winter adventures, an exciting project was conceived – to transform a standard electric bike into a version adapted for winter conditions.

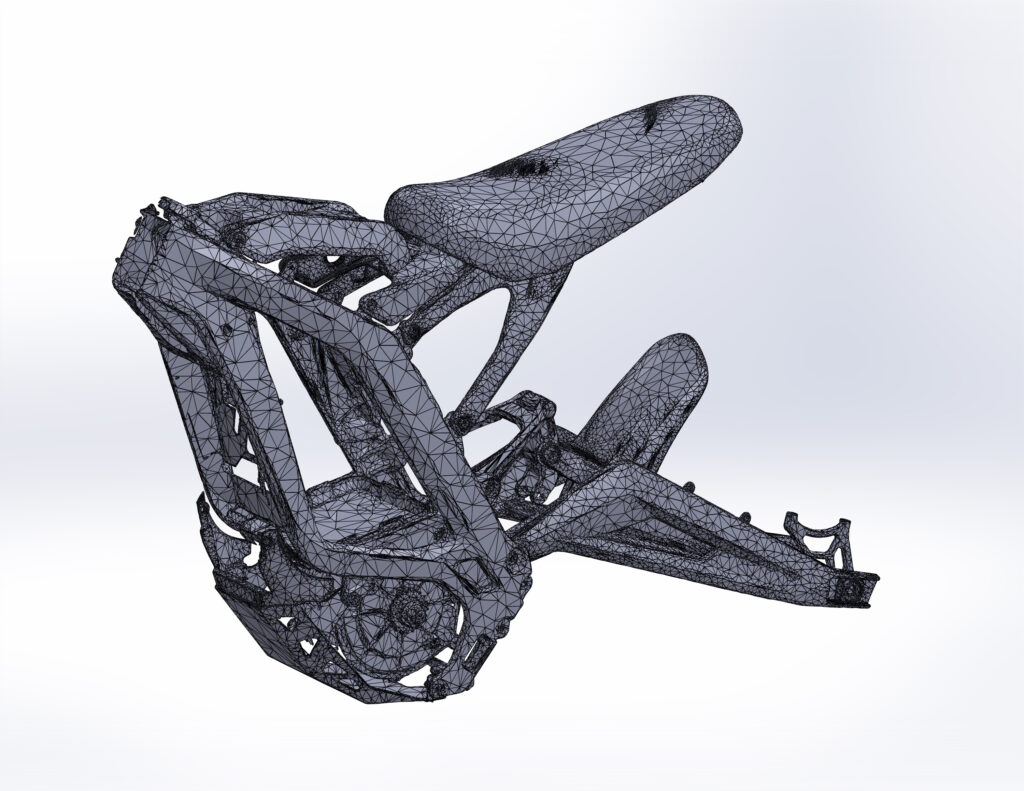

1. 3D Scanning:

Unlike photogrammetry, a professional 3D scanner was used to obtain more accurate measurements of the bike. This method allowed to get high-quality data without the need for extensive post-processing.

2. Post-processing:

Thanks to the use of a 3D scanner, it was possible to minimize the time and effort required for data processing. This ensured a faster transition to the next stages of the project compared to traditional photogrammetry.

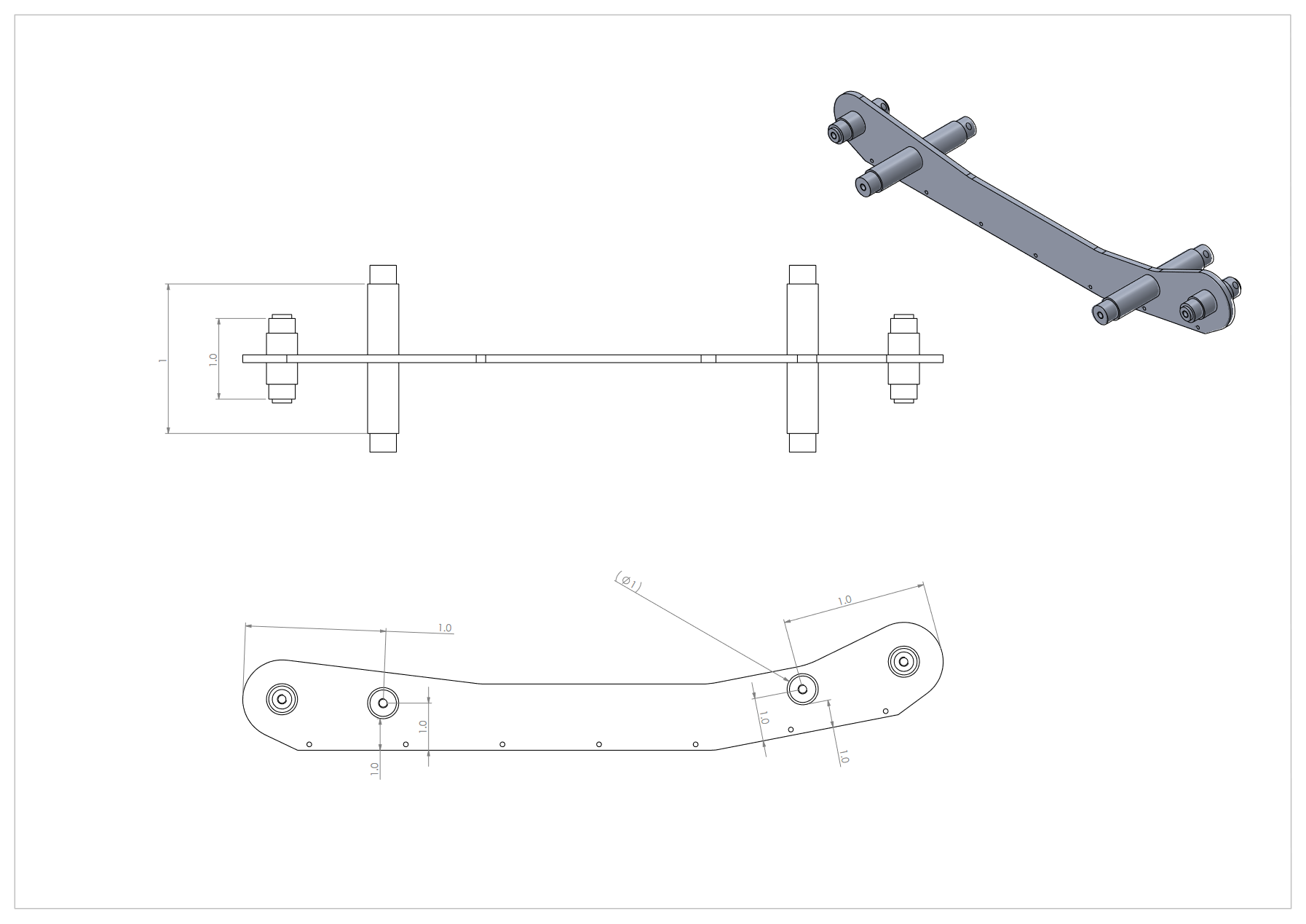

3. Creating 3D models of components:

Having gathered all the necessary data, we began developing detailed 3D models of each bike part required for its adaptation to winter conditions.

4. Preparation of drawings for manufacturing:

Based on the models, a complete set of technical drawings required for the manufacture of new parts was created. This ensured the accuracy and efficiency of the production process.

5. Implementation of the winter version:

After all the necessary parts were manufactured, the bike was assembled, resulting in a fully functional vehicle for winter conditions. The modified electric bike not only retained its core functions but also gained new qualities, making it an ideal choice for winter rides in the snow.